For certain industries such as space technology, semiconductor production, medical equipment, etc. achieving consistent and reliable bolt preloads is critical for the performance and integrity of bolted joints. Underestimate the level of variation in thread friction and surface conditions, can undermine the precision of the applied torque. Inaccurate installation can result in unintended movement, uncontrolled stresses in the assembly and fatigue. In extreme cases, leading to joint failure.

Materials such as stainless-steel nickel alloys and titanium, these frictional inconsistencies can also be compounded by galling, an adhesive wear phenomenon that can seize or damage fasteners during tightening.

The problem of friction variability

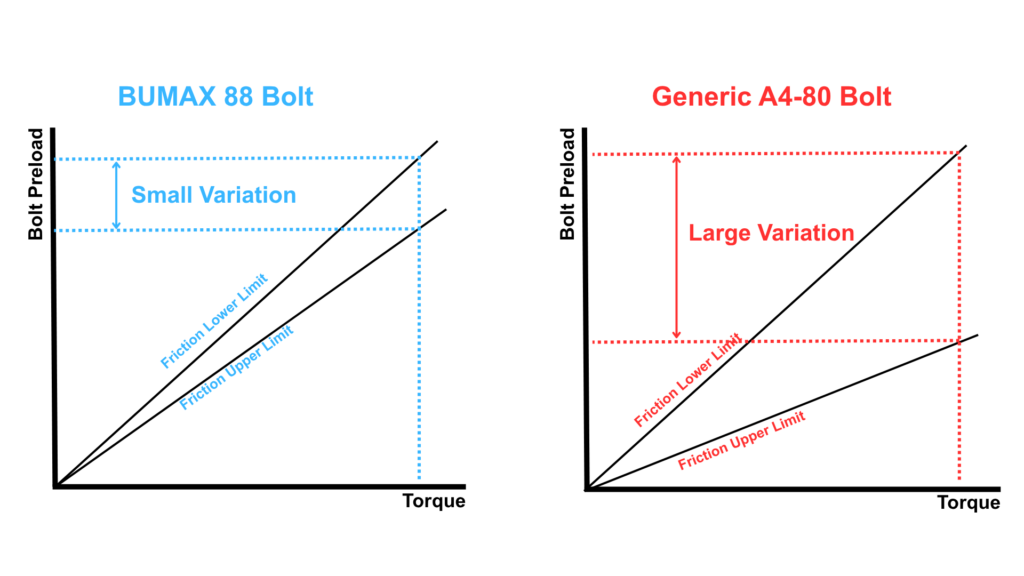

When a setting torque is applied to a bolt, typically only 10–20% of that energy is converted into a tensile preload in the bolt. The remainder is lost to friction, about half in the threads and half under the bearing surface. Therefore, any variation in friction has a direct and often magnified effect on the resulting bolt tension.

This inconsistency can result in under-tightening (leading to joint separation or vibration loosening) or over-tightening (causing yielding or gasket crushing). Factors such as surface roughness, contamination and lubrication all contribute to unpredictable frictional behaviour.

Why preload accuracy matters

Bolt preload determines how well the joint resists external loads, vibration, and fatigue. If preload is too low, cyclic loading can cause micro-movement and loosening. If it’s too high, the bolt may yield or the joint material may deform. Achieving the correct, repeatable preload therefore depends on stable friction characteristics, consistent material properties and precision manufacturing.

Galling- when friction becomes catastrophic

Galling is an extreme adhesive wear that occurs when two metal surfaces, such as bolt and nut threads seize under high contact pressure. Generic stainless fasteners are prone to galling. Microscopic asperities on the thread surfaces shear off the protective oxide layer, exposing bare metal that adheres under frictional heat. As tightening continues, material transfers between the mating threads, leading to a rapid increase in torque and eventual seizure. Galling can also prevent the development of a predictable, uniform preload, a risk in high-integrity applications.

How BUMAX® fasteners provide more accurate preloads

BUMAX® fasteners are manufactured from premium stainless steel, using controlled production processes that minimize surface roughness and variation in frictional behaviour. The production tolerances on BUMAX threads ensures a better fit between bolts and nuts. Cold-rolling of threads means that surfaces are smoother and benefit from higher surface hardness. This more even stress distribution helps to minimise galling initiation sites. BUMAX product grades such as BUMAX 109, DX 129 and SDX 109 are waxed during production. This dry film wax coating also helps to control the friction coefficient of BUMAX fasteners.

Compared with generic stainless-steel bolts, BUMAX® fasteners typically exhibit lower and more consistent coefficients of friction, meaning that the torque-to-tension relationship is far more predictable. In clean and/or precision applications, then a range of special surface treatments are available to offer even higher levels of friction control and accuracy. For critical joints, where preload accuracy is vital this predictability translates directly into higher reliability and longer service life.

Reliable fastening for demanding environments

Through superior materials engineering and manufacturing precision, BUMAX® fasteners enable engineers to achieve accurate, repeatable preloads while mitigating the risks of galling and thread seizure. The outcome is safer, longer-lasting, and more dependable bolted joints- even in the world’s toughest operating conditions.

In environments where corrosion resistance and mechanical reliability must coexist, such as semiconductor manufacturing, medical engineering and space technology, the combination of controlled friction, anti-galling performance, and high mechanical strength makes BUMAX® stainless steel fasteners the ideal choice.

BUMAX will be exhibiting at both the Semicon Europa and SpaceTech during Novemeber. For further information on these two events: https://bumax-fasteners.com/newsroom/in-the-media/bumax-exhibitions-2025/