By systematically improving sustainability in our business, we hope to become a more relevant partner for increasingly demanding customers.

Environmental policy and ISO 14001

We have our own Environmental Policy and follow the Environment Policy of our parent company Bufab. BUMAX was one of the first companies in its industry to be certified according to ISO 14001. The certification helps us to manage our environmental impacts by minimizing negative impacts, ensuring we comply with regulations, and continuously improve our performance.

Energy efficiency

BUMAX has made various energy efficiency investments in recent years, which have more than halved our energy for electricity and heating in Åshammar between 2007 and 2019. Investments to reduce our heating demand include the installation of additional insulation and energy efficient windows. Electricity use has been decreased through investments in low-energy lighting and lighting motion sensors.

By using less energy for heating and electricity, BUMAX has realized financial savings of around SEK 1.2 million each year compared with 2007. We have been identified as a good example by the Swedish Energy Agency for our efforts to promote energy efficiency.

100% renewable electricity

BUMAX sources 100 percent of its electricity from renewable hydroelectric power plants. In 2019, we used approximately 1,249 MWh of renewable electricity.

Download our 100% renewable energy certificate for 2019

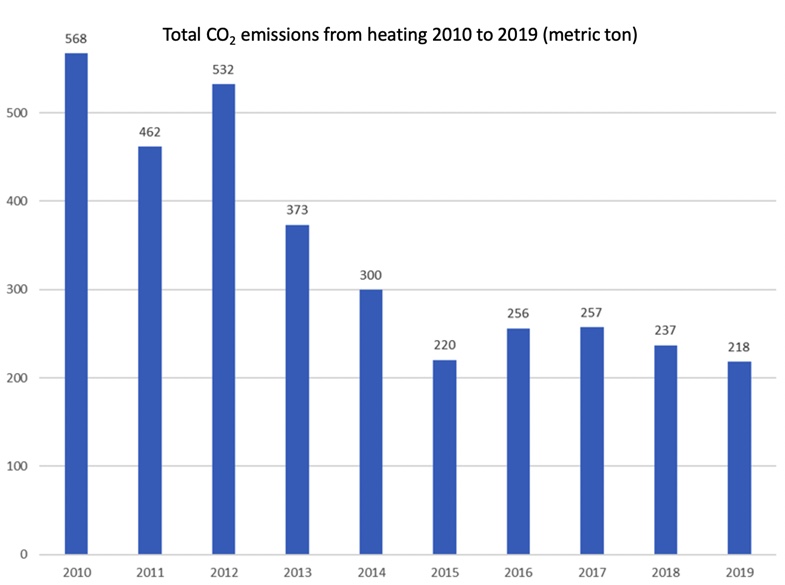

Reduced carbon emissions

By reducing the amount of energy we use at our factory in Åshammar and by sourcing renewable electricity, we have significantly reduced our carbon emissions in recent years.

Minimal emissions – other substances

BUMAX releases very small amounts of emissions and effluent. The only emissions we produce are from ventilated factory air, which is well filtered to ensure negligible emissions. The small quantity of wastewater we produce is collected and processed by a specialist waste contractor.

Waste management

Our factory in Åshammar has good waste management procedures to ensure waste materials are well sorted and ultimately recycled. Different types of waste steel are carefully sorted to ensure we get the highest possible return for valuable and highly-recyclable stainless steel. 100% of our waste steel is recycled. We properly manage and dispose of potentially hazardous waste, such as waste process oils.

Safety – constant improvement work

Our safety, incident and illness rates are consistently below the industry average. Safety is an initial topic for all factory team meetings, employee inductions and visitors, and the BUMAX Management Team assesses our safety and incident performance every month.

Risk assessments are conducted five times a year together with employees and external consultants. The assessments often focus on a particular theme and identify what improvements can be made. All incidents, including ‘near-miss’ reported incidents, are also assessed to identify what happened or could have happened, and what can be done to avoid a similar incident in the future.

Employee well-being

We have recently focused on ergonomy in our factory and offices. An external consultant makes an assessment each year on how ergonomy can be improved at our machines and desks. They also advise individual employees on ergonomy. Significant recent ergonomy investments include a more automated production to avoid heavy lifting in our wire drawing area.

Every employee is a member of our Employee Association, which organizes free time activities. As an employer, we also offer our employees healthcare and fitness contributions.

Our employees were very much involved in a 2018 project to develop our values at BUMAX. The workshop sessions with employees received positive feedback.

Diversity

In accordance with the Bufab Human Resource Policy – we treat people fairly, do not accept discrimination, promote diversity, conduct our business in an ethical manner and support our employees’ right of free association. Approximately 30% of our employees are female.