Completed in April 2025, the investment has enhanced our advanced testing capabilities – and ultimately our ability to deliver exceptional quality to customers. Customer requirements are particularly high in industries such as the semiconductor, science and space industries.

Taking fastener quality to the next level

BUMAX fasteners are well-known for their high level of quality and consistency across batches. This investment gives us the advanced tools to even better verify the quality of our products and more transparently respond to the highest customer demands.

“Our customers are increasingly demanding even greater quality and verification to meet their demanding applications and the latest standards,” explains Jonas Forslund, Production Engineer at BUMAX. “In response, we have invested in our in-house capabilities in the form of new equipment and competence.”

“At BUMAX, we sell high-quality products and it’s essential that we remain relevant in the market by continuing to be able to meet the highest demands of our customers,” explains Jonas Nilsson-Öst, Quality Manager at BUMAX. “This goes beyond our products to offer services and testing capabilities that enable the customer to fine-tune and further improve their fastener applications.”

Meet our new testing capabilities

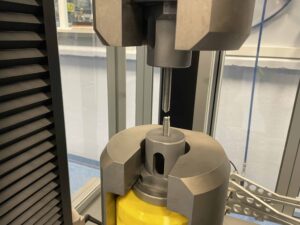

Some of the new equipment has already improved quality for all BUMAX batches, such as our new 120-ton and 25-ton tensile testing machines, which are used to determine the strength and deformation behavior of fasteners from every batch before it leaves our factory. The machines communicate directly with our certification software to automatically provide test reports in accordance with ISO 16228 (EN 10204) 3.1 or 3.2, while reducing the risk of human error and increasing productivity.

The new optical measuring machine accurately measures the dimensions of fasteners, including anomalies up to 0.0001 mm, which is about a thousandth of what is visible with the naked eye. This precise measurement improves our quality control processes and significantly reduces the potential for human error.

“We already have high sampling rates, but we see opportunities to implement more automated sorting and scanning in the future to even further enhance quality,” says Nilsson-Öst. “We are also increasingly integrating our testing capabilities by implementing interconnected digital systems that share and analyze data.”

The new microsample lab line is a significant enhancement to the BUMAX R&D lab’s testing capabilities. It features advanced equipment for cutting, hot mounting and grinding/polishing, to enable the preparation of embedded specimens of our products. This enables us to analyze our products with a microscope to verify quality on a microscopic scale.

An important part of the investment is data consolidation software that combines datapoints from multiple machines and sources, which provides deep insight into material and manufacturing quality. The analyses from the software can help us to finetune our manufacturing processes to further enhance quality.

“Our new capabilities can also support future product development, such as by verifying a new stainless steel material or production capabilities,” concludes Forslund. “In addition to our new equipment, we’ve employed an additional person to work with testing and have trained our existing technicians on the latest techniques and standards. These investments in our personnel are just as important as our equipment investments.”