Fasteners. Just How Consistent, is Consistent?

For certain high-tech manufacturing industries (e.g. semiconductor manufacturing, space technology and medical equipment), this question about fasteners will have more importance than many might first appreciate.

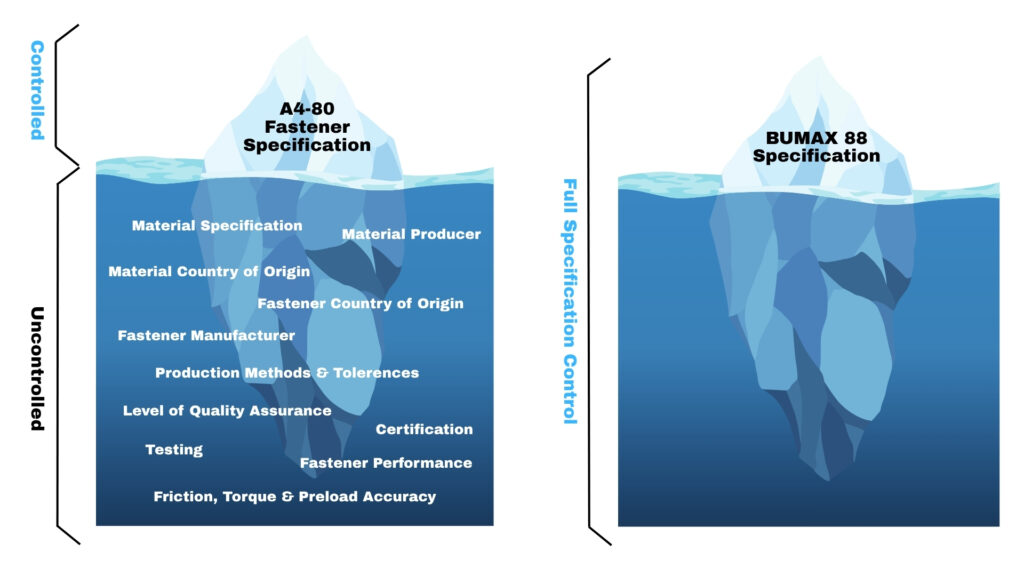

Commodity stainless steel fasteners can originate from different manufacturers and this can be difficult to specify and control. Material sources for the fasteners may come from different suppliers, all with variable melt practices, alloy windows, and process controls. Different heats of steel may meet the wide specification limits (e.g. A2 or A4) but diverge in inclusion content, nitrogen or molybdenum levels, and work-hardening response. Then there are the manufacturing practices- wire drawing reductions, heading speeds, thread rolling die condition can all result broader dispersion of tensile/yield, elongation, hardness, magnetic permeability and corrosion performance from lot to lot.

Even products carrying the same nominal grade (e.g., A2-70 or A4-80), can vary substantially. In regulated or mission-critical sectors, this variability often shows up as unexpected torque scatter or pre-loads, making it difficult to guarantee installation accuracy, premature relaxation or inconsistent service life.

BUMAX fasteners are designed around a well-defined family of premium stainless grades and manufactured through a series of tightly controlled processes, together resulting in highly consistent mechanical and corrosion-resistance performance.

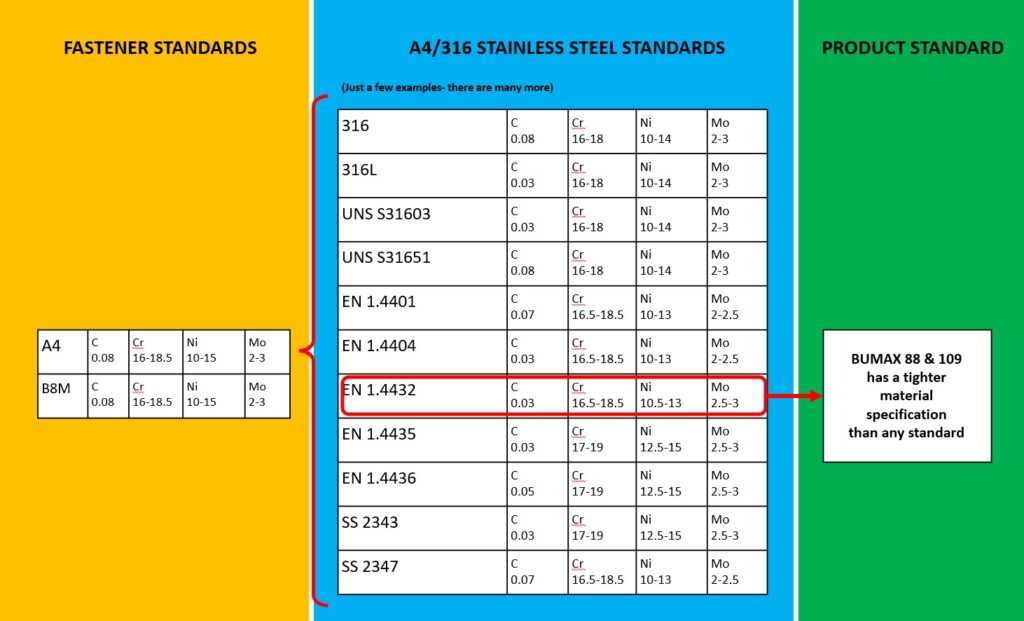

A defining feature of BUMAX product consistency is the tight control of alloying content and high quality of the base materials. BUMAX material is sourced solely from premium European producers. In addition to this, BUMAX enforces ridged specifications and narrow tolerances on composition and material quality. This cleaner steel approach reduces wide variations in mechanical performance, magnetic permeability, stability and corrosion resistance. Highly tuned manufacturing processes, tight production parameters, product tolerances and stringent quality control applied on each product production batch ensure that BUMAX products all behave in the same way. This means that when a joint is qualified based on BUMAX product grades, the joint behaviour and performance will be within tight scatter bands, something that is difficult to guarantee with generic stainless-steel fasteners.

Then there is the documentation and certification dimension. All BUMAX production is fully tested, with 3.1 product test certification available on all products. This BUMAX 3.1 certification is on the actual finished product (not a mill certificate on raw material, which is unlikely to accurately reflect the performance of the finished product). In addition, BUMAX 3.1 certificates can easily be cross referenced to the information on the box labels, providing additional reassurance.

In short, BUMAX fasteners deliver consistency by narrowing every variable that matters: alloying windows, steel cleanliness, and manufacturing processes. That discipline produces predictable strength, fatigue resistance, magnetic behaviour, and corrosion performance across batches. Generic commodity fasteners, assembled from diverse mills and makers, can meet minimum standards—but with wider scatter and fewer guarantees about how one shipment will compare to the next. For applications where bolt behaviour is safety-critical, difficult to access, or costly to re-work, BUMAX reduces variability and risk.

BUMAX will be exhibiting at both the Semicon Europa and SpaceTech during November. For further information on these two events: https://bumax-fasteners.com/newsroom/in-the-media/bumax-exhibitions-2025/